Recovery of Oil on Snow and Ice Calculator (ROSI)

User Manual

The ROSI Calculator is intended to assist with the development and verification of Oil Spill Response Plans that include tactics for recovering oil on snow and ice using "Yellow Iron" equipment.

Prepared by NORTECH, Inc

In partnership with BSEE (Bureau of Safety and Environmental Enforcement).

Revised August 31, 2023

User Manual

Table of Contents

- About

- Tooltips

- Introduction

- Abbreviations

- Unit Abbreviations

- Definitions

- Assumptions and Limitations of the ROSI Calculator

- Unit Systems (US Customary / Metric)

- Optional Tools (Plume Area Calculations and Contaminated Snow Volume Calculations)

- Task Working Areas

- ROSI Calculator Inputs (Descriptions and Definitions)

- Main Inputs - Recovery and Handling Capacity Scenario Verification

- Advanced Options - Recovery and Handling Capacity Scenario Verification

- ROSI Calculator Outputs

- Download PDF

- User Inputs

- Equipment Verification

- Handling and Recovery Verification Results

- Warnings

- Simplified Example Scenario - Analysis and Verification

- Using the ROSI Calculator with the Simplified Scenario

- Formulas Used

- List of Figures

- Figure 1: Blowout Plume Map

- Figure 2: Plume Area Calculations Example

- Figure 3: Plume Volume Calculations Example

- Figure 4: Simplified Example TWA - A Inputs

- Figure 5: Simplified Example TWA - B Inputs

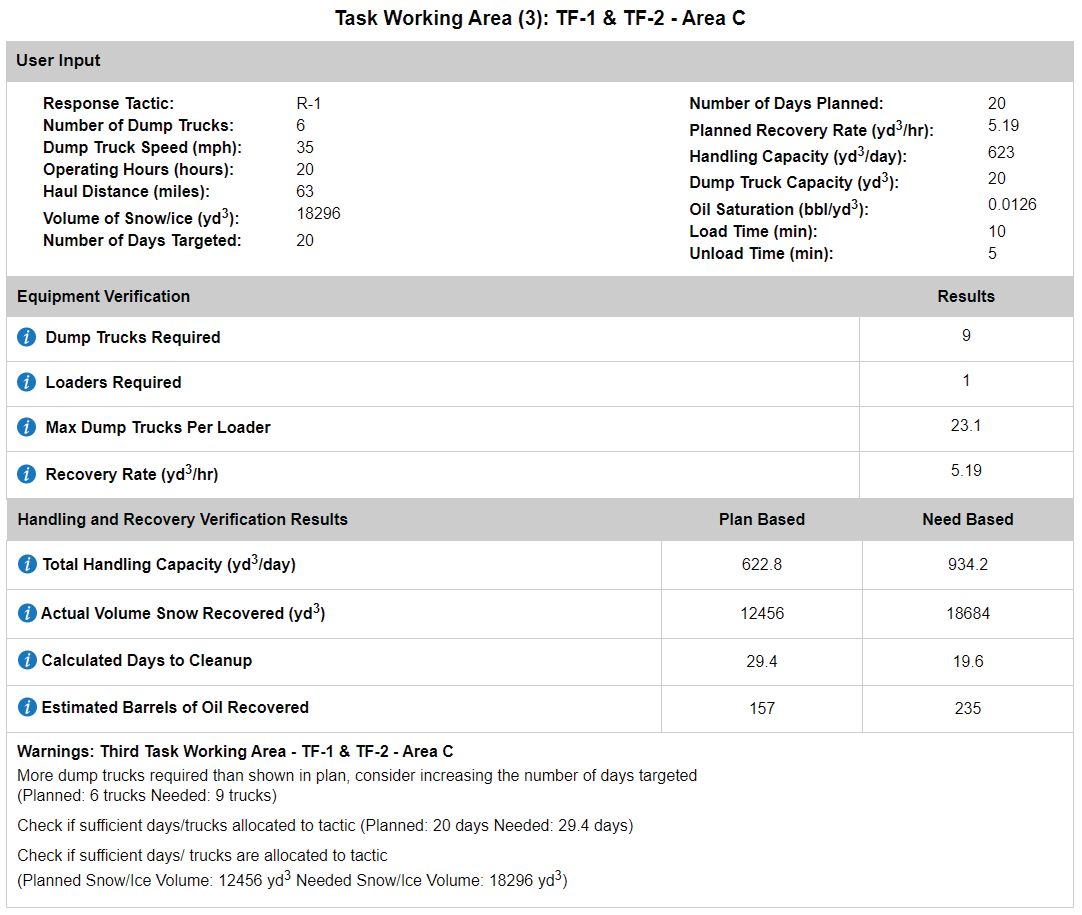

- Figure 6: Simplified Example TWA C - Inputs

- Figure 7: Output - Task Working Area A

- Figure 8: Output Task Working Area B

- Figure 9: Output Task Working Area C

- List of Tables

About

The Recovery of Oil on Snow and Ice (ROSI) Calculator was developed from February 2022- February 2023 as part of the Bureau of Safety and Environmental Enforcement (BSEE) Project 1142: Research to Support Analysis of Oil Spill Response Plans for Spill on Snow and Solid Ice. ROSI was originally developed using United States Customary Units (USCU) and then expanded to include metric units. The ROSI Calculator is hosted on the BSEE website and can be located at the following web address: https://www.bsee.gov/what-we-do/oil-spill-preparedness/response-system-planning-calculators

Tool Tips

Tool tips have been provided in the ROSI Calculator input and output screens. Hovering over a tooltip will provide definitions and other useful information directly embedded within the Calculator. Clicking the User Manual link within a tooltip will open the relevant section of the User Manual in a new browser tab.

Introduction

Oil spills in the arctic sometimes occur on land during the winter season, resulting in oil contaminated snow and/or ice. Cleanup of these spill sites using heavy earth moving equipment is covered in tactics provided in the Alaska Clean Seas (ACS) Technical Manual (TM). These tactics, sometimes referred to as "yellow iron" or "yellow gear" tactics involve transporting contaminated snow or ice to a treatment facility using trucks. Often the limiting factor of the cleanup is the quantity of trucks available for the spill response. Ensuring that the proper quantity of heavy equipment and especially trucks are available is critical in timely response to spills.

The ROSI Calculator estimates the resources necessary to implement specific spill response tactics described in the ACS TM (revision 15, June 2021) to clean up an oil spill on snow and solid ice. The tactics utilized for ROSI are:

- Tactic R-1: Mechanical Recovery of Lightly Oiled Snow (utilizes equipment such as loaders, dump trucks, and dozers to recover lightly oiled snow)

- Tactic R-3: Recovery of Oil-Saturated Snow (utilizes equipment such as skid-steers, loaders, dump trucks, and dozers to recover oil-saturated snow)

- Tactic R-5: Recovery of Embedded Oil (utilizes equipment such as loaders, dump trucks, trimmers to recover oil embedded in ice)

- Tactic R-29: Ice Mining (utilizes equipment such as ice miners, loaders, dump trucks, trimmers to recover oil embedded in sea-ice rubble piles)

Depending on the inputs provided, ROSI can estimate the:

- Number of dump trucks and loaders needed to clean up within the targeted cleanup time

- Days to achieve cleanup

- Maximum number of dump trucks that can operate congruently per loader

- Actual recovery rate for one dump truck

- Actual volume of snow/liquid recovered

- Total Handling Capacity of loaders and dump trucks (CY/day)

- Actual barrels of oil recovered

The estimates include both plan-based and need-based results. Plan-based results are primarily based on the number of dump trucks and days allocated in the plan itself, whereas need-based results are primarily based on the volume of contaminated snow and the targeted cleanup time.

The ROSI Calculator is applicable to any recovery of contaminated ice and snow, following control of a continuous discharge of oil (e.g., well blowout) or an instantaneous discharge of oil.

This User Manual provides information for the user on how to use the ROSI calculator. This includes information on the data inputs that must be entered for each set of response tactics being applied to an individual recovery zone.

The ROSI Calculator was originally developed by NORTECH, Inc. in consultation with and with funding from the U.S. Department of the Interior, Bureau of Safety and Environmental Enforcement (BSEE).

To use the Calculator, estimates or actual data from an oil spill response plan scenario would be entered into the appropriate fields, such as the one-way distance from the recovery zone to the offload zone, average transit speed, system loading and unloading time, operating time, amount of contaminated material in a recovery zone or the area of a recovery zone and depth of recovery. ROSI then returns the output (i.e., number of dump trucks/ loaders required, recovery rate, handling capacity, volume recovered, etc.)

Recovery operations are estimated by the ROSI Calculator without regard to the type of spill and without distinguishing between a batch spill, such as a fuel tank rupture, or a previous ongoing spill, such as a well blowout. When multiple response tactics are combined in a recovery zone, ROSI's output will be compared with the data presented by the plan writer to determine whether their proposed plan will adequately address the quantities of contaminated material.

While a few inputs are mandatory in order to obtain an output, most inputs have default values in the event that the field is left blank, and a few inputs are optional. This User Manual elaborates further on this aspect.

While every effort has been made to make ROSI a robust planning tool, it should be noted that it is not intended to be used during a spill response. Many safety factors such as the strength of sea ice, sea ice loading of multiple systems, speed limits of loaded trucks and other factors have not been included in the calculator. See the Assumptions and Limitations of the ROSI Calculator section of this manual for additional discussion.

Abbreviations

- Alaska Clean Seas

- Bureau of Safety and Environmental Enforcement

- oil spill response plan

- oil spill removal organization

- Recovery of Oil on Snow and Ice Calculator

- Technical Manual

- Task Working Area

- United States Customary Units

Unit Abbreviations

Unit abbreviations used in ROSI are presented Table 1 in the section titled: Unit Systems (US Customary / Metric).

Definitions

Alaska Clean Seas (ACS): Not-for-profit oil spill response cooperative whose membership includes oil and pipeline companies that engage in or intend to undertake oil and gas exploration, development, production, or pipeline transport activities on the North Slope of Alaska. ACS is an oil spill removal organization (OSRO). The ACS Technical Manual (TM) can be downloaded from the ACS website at: https://www.alaskacleanseas.org/. The spill response tactics used in ROSI are included in the ACS TM.

Oil Spill Response Plan (OSRP): A BSEE-regulated plan developed by an owner or operator of an offshore facility that must demonstrate a quick and effective response whenever oil is discharged.

Dedicated Dump Truck: Single dump truck and operator(s) exclusively used for one oil spill response task force.

Plan Writer: The party responsible for developing an OSRP, typically on behalf of the owner.

Recovery Zone: The area affected by a spill of oil where recovery is being attempted.

Task Working Area: The area assigned to a task force where one or more spill response tactics occur.

Plan-based: Output of the ROSI Calculator based on the number of dump trucks and days allocated in the plan. The plan-based results answer the question: "What kind of spill recovery and handling capacity could we expect if we followed the plan (number of loaders / dump trucks and planned days)?"

Need-based: Output of the ROSI Calculator based on the volume of contaminated snow and a targeted cleanup time. The need-based results answer the question: "What kind of spill recovery and handling capacity could we expect if we used the required number of loaders and dump trucks to complete the cleanup in the targeted time?"

Assumptions and Limitations of the ROSI Calculator

The ROSI Calculator was developed to provide estimates using the formulas provided in ACS tactics for "yellow iron" equipment such as dozers, loaders and dump trucks performing removal and transportation of contaminated snow and ice. In real world conditions, mechanical recovery of contaminated materials is commonly limited based on the number of dump trucks. This is due to the relatively short time it takes to load a dump truck compared to the much longer transit time. Similarly, the outputs for the response tactics addressed by ROSI are typically limited by the transport capabilities of the dump trucks assigned to the task force. However, ROSI can estimate the minimum number of loaders or other equipment required, based on the loading rates provided in the ACS tactics.

Environmental Conditions: The ROSI Calculator and ACS Technical Manual assumes that conditions at the recovery zone are amenable to deploying the tactics and equipment. Adverse conditions may delay recovery efforts.

Seasonal Conditions: The response tactics used in the ROSI Calculator are focused on recovery of contaminated ice and snow during winter scenarios, ROSI does not incorporate recovery of pooled free oil or any non-ice or non-snow contaminated material (such as gravel).

Mandatory Values: The ROSI Calculator requires the following three inputs to function, including:

- Spill Response Tactic (R-1, R-3, or R-5/R-29)

- One-Way Haul Distance from Recovery Area to Offload Area (miles or kilometres)

- Volume of Contaminated Snow/Ice (cubic yards or cubic metres)

Default Values: The ROSI Calculator allows for all data inputs to be modified by the user, including the default values. Default values are either directly incorporated from the ACS tactics, or were selected to ensure results were conservative in nature. Default values are listed in parentheses as follows:

- Number of Dedicated Dump Trucks (1)

- Dump Truck Capacity (20 cubic yards (yd3/15 m3))

- Average Dump Truck Transit Speed (35 mph/55 km/h)

- Dump Truck Load Time (10 minutes)

- System Unload Time (5 minutes))

- Oil Saturation (note: 1 cubic yard is equivalent to approximately 4.8 barrels of oil in volume or 0.76 cubic metres)

- Lightly saturated snow

- 0.3 bbls/yd3 (USCU)

- 0.06 m3 oil / m3 snow (metric)

- Highly saturated snow

- 2.4 bbls/yd3 (USCU)

- 0.5 m3 oil / m3 snow (metric)

- Oil embedded in ice or ice mining

- 0.125 bbls/yd3 (USCU)

- 0.03 m3 oil / m3 snow (metric)

- Lightly saturated snow

- Operating Hours (20 hours per day)

- Recovery Rate of non-Dump Truck Equipment (Calculated)

Optional Values: The user may input the following optional values including:

- Number of Days Targeted

- Number of Days Planned

- Planned Recovery Rate

- Planned Handling Capacity Rate

The use of the optional values is described in greater detail in the Optional Tools section of this manual.

Asset Mobilization: The ROSI Calculator assumes that equipment is deployed to the recovery zone and ready to operate. For the response tactics that ROSI addresses, this is generally a true assumption as the equipment can be readied while the source of the discharge is being secured. Mobilization and demobilization are therefore assumed to not impact the recovery rate of any deployed assets.

Limitations: Safety considerations such as the need to avoid the resonant speed for moving heavy loads on floating ice sheets as a function of water depth have not been included in the calculator. For example, while experts advise that dump truck speeds may not be a factor for ice roads constructed over deeper water or very shallow water where the ice is grounded, decelerating through the "critical speed zone" (typically 12-15 miles per hour (mph)/19-24 kilometers per hour (km/h)) in certain water depths can cause sudden buckling failure of the ice sheet and major damage to the ice road. During an actual spill response it is expected that operations will factor these variables into transit times, with appropriate speed restrictions along certain sections of the route. There is a lot of published material on this phenomenon which, although not a significant issue for light vehicles like crew cabs, can become a major factor for moving heavy vehicles like tandem dumps and loaders. Safe parking times is another factor that would need to be accounted for within the active loading area for heavy vehicles waiting to load or in the process of loading. ROSI is intended as a planning (OSRP analysis) tool only. Refer to the Final Report – Revised for citations regarding floating ice roads.

Unit Systems (US Customary / Metric)

Plume Area Calculations

ROSI supports US customary units as well as metric units. Clicking the slider at the top of the input page switches between unit systems.

US Customary Units

US Customary Units

Metric Units

Metric Units

Units and abbreviations utilized are listed in Table 1.

| Measurement in ROS | US Customary Units (abbreviation) |

Metric Units (abbreviation) |

|---|---|---|

| Speed | Miles per hour (mph) | Kilometres per hour (km/h) |

| Time | Hours/minutes (hr/min) | Hours/minutes (hr/min) |

| Haul Distance | Miles (miles) | Kilometres (km) |

| Volume of Snow/Ice | Cubic yards (yd3) | Cubic metres (m3) |

| Planned Recovery | Cubic yards per hour (yd3/hr) | Cubic metres per hour |

| Planned Handling Capacity Rate | Cubic yards per day (yd3/day) | Cubic metres per day (m3/day) |

| Dump Truck Capacity | Cubic yards (yd3) | Cubic metres (m3) |

| Oil Saturation | Barrels per cubic yard (bbl/yd3) | Cubic metre (oil) per cubic metre (snow) (m3 oil/m3 snow) |

| Load/Unload Time | Minute (min) | Minute (min) |

| Oil Recovered | Barrels (bbl) | Cubic metres (m3) |

| Snow Depth | Inches (in) | Centimetres (cm) |

| Area | Square feet (ft2) | Square metres (m2) |

Optional Tools (Plume Area Calculations and Contaminated Snow Volume Calculations)

Plume Area Calculations

The "Plume Area Calculations" sub-calculator is an optional, self-contained calculator within the overall ROSI Calculator. This sub-calculator can be used to verify the square footage/square metres of the triangular and trapezoidal work areas within a plume area. The area information calculated in the "Plume Area Calculations" can be entered as inputs in the "Contaminated Snow Volume Calculations" sub-calculator, described in the paragraph that follows. The information entered in this sub-calculator will not affect the operation or output of the main calculator in any way.

Contaminated Snow Volume Calculations

The "Contaminated Snow Volume Calculations" sub-calculator is an optional, self-contained calculator within the overall ROSI Calculator. This sub-calculator can be used to verify the volume of expected contaminated snow or ice based on the average depth of contamination in a work area. The information calculated in the "Contaminated Snow Volume Calculations" can be entered as a volume of Snow/Ice (yd3/m3) in the Recovery and Handling Capacity Scenario Verification for one or more task areas in the Task Working Areas section that follows. The information entered in this sub-calculator will not affect the operations or output of the main calculator in any way. The sub-calculator results, however, would normally be entered into the main ROSI Calculator in the "Volume of Snow/Ice" data entry field.

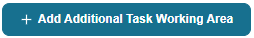

Task Working Areas

A task working area (TWA) denotes a geographic recovery zone and the tactic that would be employed in it. If multiple tactics are to be employed in the same recovery zone, then each tactic used would require its own separate TWA. A total of 10 TWAs are supported by the ROSI Calculator at one time. To add an additional TWA click the button at the bottom of the input page.

To remove a TWA (when two or more are selected) click the delete button in the top right of the TWA to be deleted.

Note: The first TWA is required and cannot be deleted.

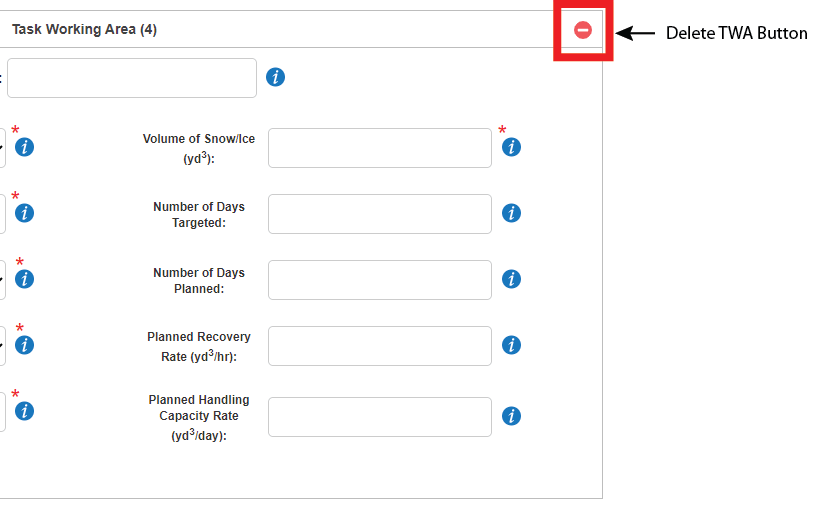

ROSI Calculator Inputs (Descriptions and Definitions)

Main Inputs - Recovery and Handling Capacity Scenario Verification

The following describes the inputs for the "Recovery and Handling Capacity Scenario Verification" section of ROSI. Not all the inputs listed are mandatory in order to perform the output calculations. However, ROSI will provide the most valuable output if the information contained in the OSRP is correctly understood by the user and entered correctly as inputs. Default values and assumptions made in the OSRP should be verified as reasonable for the given scenario prior to them being used in ROSI.

Task Force Name (optional)

The user may enter a name for the task force operating in the TWA if desired.

Response Tactic (mandatory)

The input of a response tactic is used primarily to assist in determining the oil saturation of the snow expected. The following oil saturation values are used by default depending on the response tactic chosen from the drop-down menu.

- Tactic R-1: Mechanical Recovery of Lightly Oiled Snow

- 0.3 bbls/yd3 (USCU) default oil saturation

- 0.06 m3 oil / m3 snow (metric) default oil saturation

- Tactic R-3: Recovery of Oil-Saturated Snow

- 2.4 bbls/yd

- 3 (USCU) default oil saturation

- 0.5 m3 oil / m3 snow (metric) default oil saturation

- 0.125 bbls/yd3 (USCU) default oil saturation

- 0.03 m3 oil / m3 snow (metric) default oil saturation

Saturation levels used in tactics R-1, R-3 and R-5 are defined in the ACS TM. The saturation level used for tactic R-29 is incorporated from tactic R-5. Oil saturation values may be edited in the advanced options of the input.

The ROSI Calculator does not support other response tactics listed in the ACS TM.

Number of Dump Trucks (mandatory; default 1)

This input represents the number of sets of response equipment deployed per the OSRP.

The default and minimum value for this input is 1 (one) and should be entered as a whole number. The number represents the individual number of dump trucks assigned to the tactic.

Note: If a targeted cleanup time is entered, the calculated number of Dedicated Dump Trucks needed to accomplish the task within the specified timeframe will override the entered number of Dedicated Dump Trucks.

Dump Truck Speed (mandatory; default: 35 mph/55 km/h)

The average speed for the dump truck to transit from the recovery area to the offload area. Unless stated otherwise in the plan, this speed is set to 35 miles per hour (55 km/h) as specified in the ACS TM.

Operating Hours (mandatory; default: 20 hours per day)

Number of hours that the equipment operates per day. This number is less than 24 hours in order to account for maintenance and other concerns, such as shift changes and various inefficiencies. This number is typically set to 20 hours for equipment. Personnel are limited to an effective 10 hour operating time, however ROSI assumes there will be a shift change of response personnel half way through the day. Plans may specify different operating hours.

Haul Distance (mandatory; no default, one-way miles/kilometres)

The distance from the area in which recovery operations are taking place to where recovered material is offloaded. Note this is a one-way distance and not round-trip. If the distance in a particular zone is variable over time, it is up to the user to decide whether to enter a maximum or average value. Plans typically provide a single value for each application of a tactic, rather than a variable value.

Volume of (Contaminated) Snow/Ice (mandatory; no default; cubic yards/cubic metres)

This is the volume of contaminated snow to be cleaned up within the task working area (TWA) for the specified response tactic. The number should be provided by the plan writer and may either be modeled or assumed.

Number of Days Targeted (optional)

This value typically represents the regulatory-required number of days that an operator is allotted to achieve cleanup of the TWA. It will often match the number of days listed in the plan.

Note: If this optional input is utilized, ROSI will compute the number of dump trucks and loaders required to achieve the clean-up of the specified volume within the number of days targeted. The need-based column of the output will describe the recovery and handling capacity based on these calculations.

Note: If this optional input is not utilized, ROSI will utilize the number of planned dump trucks to compute the number of days required to achieve the clean-up of the specified snow/ice volume. The need-based column of the output will describe the recovery and handling capacity based on these calculations.

Number of Days Planned (optional)

This value represents the number of days that an operator has to achieve cleanup of the TWA according to the OSRP. It will often match the number of days targeted.

Note: If this optional input is utilized, ROSI will compute the recovery and handling capacity based on the number of days planned. These calculations will be reported in the plan-based column of the output report. The calculated days to cleanup within the plan-based column will report the number of days that would be required to complete cleanup of the specified volume of snow using the number of dump trucks listed in the OSRP.

Note: If this optional input is not utilized, ROSI will compute the recovery and handling capacity based on the number of days required to clean up the TWA utilizing the number of dump trucks listed in the OSRP. These calculations will be reported in the plan-based column of the output report.

Planned Recovery Rate (optional, yd3/or m3/hr)

The planned recovery rate refers to the amount of contaminated snow/ice that a dump truck can haul each hour if operating at 100% efficiency. This rate is expressed for each single dump truck.

If the plan provides a recovery rate, it can be entered here for comparison to the recovery rate determined by the ROSI Calculator. If the planned recovery rate differs from the calculated rate by a significant amount (>5% relative percent difference) a warning will be generated.

Planned Handling Capacity Rate (optional, yd3/day or m3/day)

If the plan provides a handling capacity rate, it can be entered here for comparison to the handling capacity rate determined by the ROSI Calculator. If the planned handling capacity rate differs from the calculated rate by a significant amount (>5% relative percent difference) a warning will be generated.

This value is the total handling capacity (i.e., recovery rate multiplied by number of dump trucks multiplied by operating hours per day) and should be recalculated accordingly if the plan in question provides a different kind of handling capacity.

Advanced Options - Recovery and Handling Capacity Scenario Verification

The advanced options are values where the default values are based on ACS TM and are unlikely to change based on the scenario. By default, the advanced options menu is collapsed and must be expanded to see or modify the advanced options.

Dump Truck Capacity (default: 20 yd3/15 m3)

The default value for this input is 20 (twenty) cubic yards. This input represents the cubic yard capacity of the dump truck, which is the volume of contaminated material, that the dump truck can carry. The ACS TM provides capacity values for dump trucks available in the area.

Oil Saturation (default: based on response tactic, bbl/yd3 or m3 oil /m3 snow)

Oil saturation describes the average quantity of oil contained in each cubic yard/cubic meter of snow that is impacted by the spill within the TWA (Note: 1 cubic yard is equivalent to approximately 4.8 barrels of oil in volume or 0.76 cubic metres). Default values for oil saturation are based on the following tactics:

- Tactic R-1: Mechanical Recovery of Lightly Oiled Snow

- 0.3 bbls/yd3 (USCU) default oil saturation

- 0.06 m3 oil / m3 snow (metric) default oil saturation

- Tactic R-3: Recovery of Oil-Saturated Snow

- 2.4 bbls/yd3 (USCU) default oil saturation

- 0.5 m3 oil / m3 snow (metric) default oil saturation

- Tactic R-5/R-29: Recovery of Embedded Oil or Ice Mining

- 0.125 bbls/yd3 (USCU) default oil saturation

- 0.03 m3 oil / m3 snow (metric) default oil saturation

Oil Saturation values may be edited in the advanced options dropdown menu in the Calculator input.

Load Time (default: 10 minutes)

The time it takes to load a dump truck to capacity (input in minutes). Default loading and unloading times for tactics R-1 and R-3 are defined based on the ACS TM but may be adjusted based on information listed in the plan.

Unload Time (default: 5 minutes)

The time it takes to unload a fully loaded dump truck (input in minutes). Default loading and unloading times for tactics R-1 and R-3 are defined based on the ACS TM but may be adjusted based on information listed in the plan.

ROSI Calculator Outputs

Download PDF

The output report may be downloaded by clicking on the "Download PDF" icon  in the upper right corner of the output page. The report will be downloaded in Adobe Portable Document Format (PDF) with a page size of 8.5 inches x 11 inches (US Letter) in portrait (vertical) orientation.

in the upper right corner of the output page. The report will be downloaded in Adobe Portable Document Format (PDF) with a page size of 8.5 inches x 11 inches (US Letter) in portrait (vertical) orientation.

User Input

This area displays the input values that were used by the ROSI Calculator to compute the outputs.

Equipment Verification

Dump Trucks Required

The number of systems needed if there is a targeted clean-up time, or the number of Dump Trucks entered as an input by the user.

Loaders Required

The number of loaders required in order to operate the number of dump trucks required to achieve clean up within the targeted cleanup time.

Maximum Dump Trucks Per Loader

The maximum number of dump trucks that can be assigned to the task force, per loader, and still operate at a hypothetical 100% efficiency for the calculated recovery rate. Output number is a decimal value, so it must be rounded down. It is based on haul distance, speed, dump truck capacity, dump truck loading time and unloading time.

Recovery Rate (yd3/hr or m3/hr)

The recovery rate of contaminated snow in cubic yards or cubic metres per hour of one truck. The rate is determined based on the dump truck capacity, haul distance, speed, and loading and unloading time assuming 100% operating efficiency.

Handling and Recovery Verification Results

Total Handling Capacity (yd3/day or m3/day)

The total volume (yd3/m3) of contaminated snow/ice that can be loaded and hauled each day. The plan-based and need-based variants are dependent on user inputs for number of days targeted / number of days planned. See the input section of the User Manual for more information.

Actual Volume Recovered (yd3/m3)

The total volume of contaminated snow/ice that can be recovered. Need-based and plan-based variants of the actual volume recovered are based on the inputs of number of days targeted and number of days planned described above. Ideally this number should nearly match the input value entered for volume of (contaminated) snow/ice.

Calculated Days to Cleanup (days)

This output represents the number of days required to complete the tactic within the TWA. Need-based and plan-based variants of the calculated days to cleanup are based on the inputs of number of days targeted and number of days planned described above. Ideally this number should be less than the input values entered for number of days targeted / number of days planned.

Estimated Barrels of Oil Recovered (bbls or m3)

The estimated barrels of oil recovered within the TWA, which is calculated by multiplying the volume of contaminated snow/ice recovered and the oil saturation level of the snow/ice within that TWA. This calculation will never exceed the maximum potential recovery for the site based on the user input. The accuracy of this number is dependent upon valid assumptions regarding the average oil saturation of snow/ice within the TWA. This saturation level is difficult to estimate and in most cases this number should be viewed as a rough estimate.

Warnings

Warnings are generated for the following outcomes:

- A comparison of the number of dump trucks planned to the number needed

- The needed quantity of equipment or time is not sufficiently provided for in the plan

- The planned inputs do not match the outputs

- User inputs exceed typical limits

- Excessive speeds of dump trucks beyond typical planning capacity defaults (35 mph or 55 km/h)

Warnings include numerical comparisons within the warning to assist in highlighting the issue where applicable.

Simplified Example Scenario - Analysis and Verification

The following simplified OSRP scenaario was developed to illustrate the use of the ROSI Calculator. Intentional errors in this simplifed example scenario were included to illustrate the review functionality of the ROSI Calculator. The scenario is provided in USCU, metric equivalents would be used and generated in the metric version.

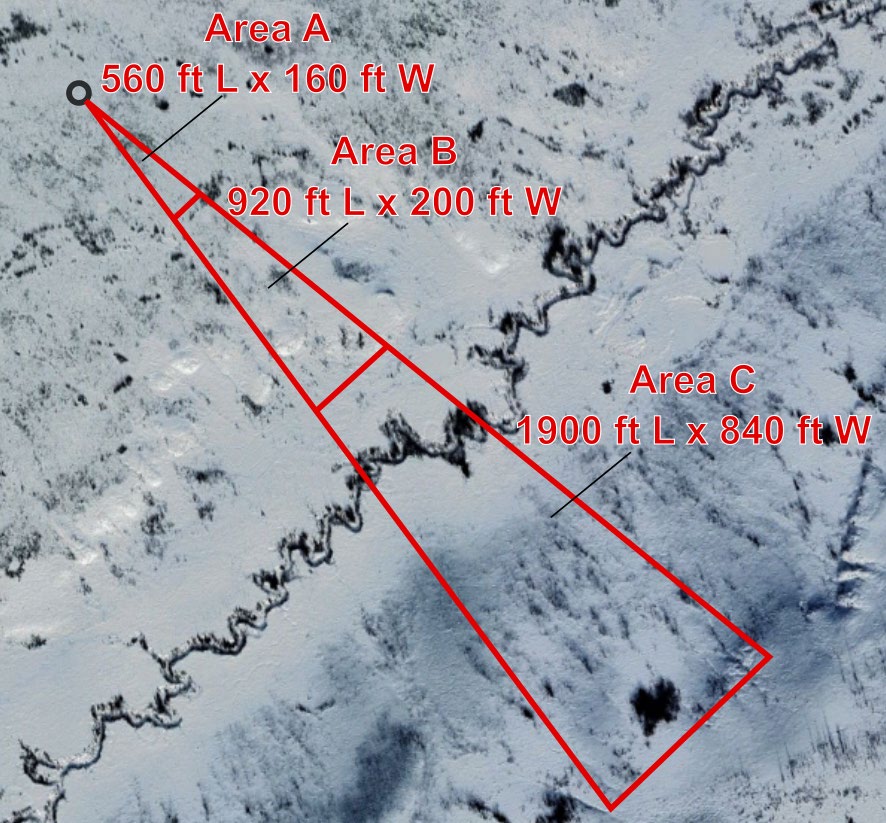

Simplified Example - Exploration Well Blowout During Winter

Figure 1: Blowout Plume Map

Figure 1: Blowout Plume Map

| Area | Area of Scattered Oil (sq ft) |

Average Depth of Fallout (inches) |

Volume of Contaminated Snow (yd3) |

Average Oil Saturation of Contaminated Snow (bbl/yd3) |

|---|---|---|---|---|

| A | 44,480 | 8.5 | 1,166 | 2.4 |

| B | 92,000 | 1.5 | 426 | 1.3 |

| C | 798,000 | 0.25 | 616 | 0.3 |

Notes:

Minimum depth of mechanical recovery is assumed to be 6 inches.

Simplified Example Continued - Exploration Well Blowout During Winter

| Spill Recovery Tactic |

Number of Systems |

Recovery System |

Oiled Snow Recovery Rate (yd3/hr) |

Handling Capacity (yd3/day) |

Volume of Contaminated Snow (yd3) |

Days to Clean Up |

|---|---|---|---|---|---|---|

| TF-1: R-3 (Area A) |

1 | Loaders: 1 Dozers: 1 Trucks: 4 |

5.19 | 415 | 1166 | 10 |

| TF-2: R-3 (Area B) |

1 | Loaders: 1 Dozers: 1 Trucks: 2 |

5.19 | 208 | 426 | 10 |

| TF-1 & TF-2: R-1 (Area C) |

1 | Loaders: 2 Dozers: 2 Trucks: 6 |

5.19 | 623 | 616 | 20 |

Notes:

Round trip haul distance to a processing facility is 126 miles.

Using the ROSI Calculator with the Simplified Scenario

In this example the use of the ROSI Calculator will be demonstrated to assist with the analysis of the simplified scenario shown in Table 3. While ROSI is intended to aid with the analysis, it is expected that the individual will apply critical thought while using ROSI. Incorrect inputs will provide meaningless outputs (garbage in, garbage out). It is ultimately the responsibility of the user to ensure that all assumptions are reasonable, and that common sense is applied.

The first step of analyzing the simplified scenario or any other plan is to read and understand the plan. Special attention should be paid to notes and references in the plan as this can change the understanding of the plan.

Plume Area Verification

Using the "Plume Area Calculations" sub-calculator, square footage of the plume area can be verified. If the optional sub-calculator is not visible, click on the dropdown arrow to present the sub-calculator.

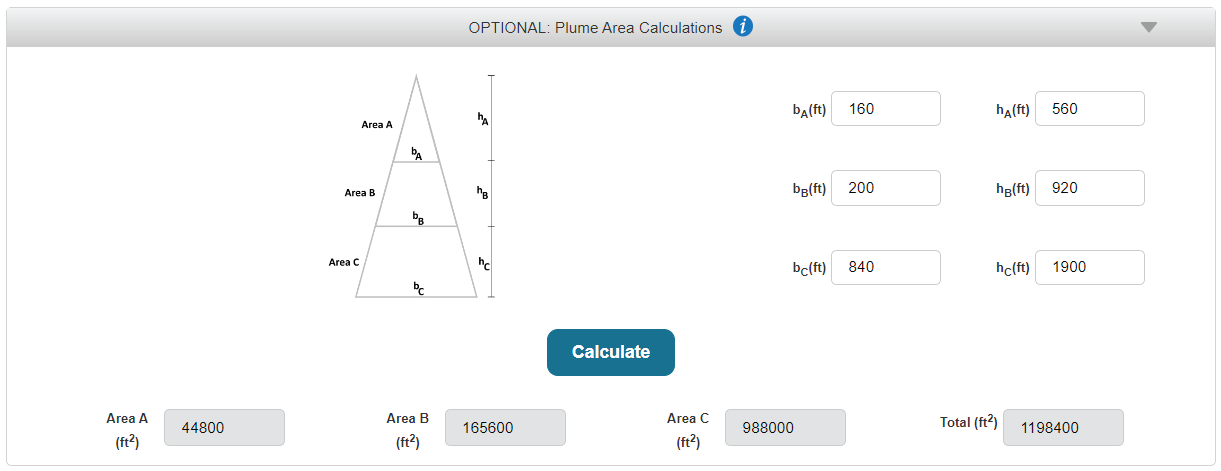

The plume area data located in Figure 1 above can be entered in the sub-calculator as shown below in Figure 2. The square footage estimates are shown as outputs.

Figure 2: Plume Area Calculations Example

Figure 2: Plume Area Calculations Example

As shown in Table 4 below, the plume area for Area A's plan matches the verification. Because the values match, we expect that the area was computed correctly. However, for Area B and Area C the plan's stated area is significantly smaller than the verification. The plan writer for this example incorrectly calculated the areas of Area B and Area C using the formula for area of a triangle instead of correctly applying the formula for area of a trapezoid. This error requires correction in the plan, as it affects the overall estimate for handling and recovery capacity.

| Area | Planned Area (sq ft) |

ROSI Verification (sq ft) |

Analysis |

|---|---|---|---|

| A | 44,480 | 44,480 | Area calculation in plan is verified |

| B | 92,000 | 165,600 | Area calculation listed in plan is incorrect |

| C | 798,000 | 988,000 | Area calculation listed in plan is incorrect |

Volume of Contaminated Snow Verification

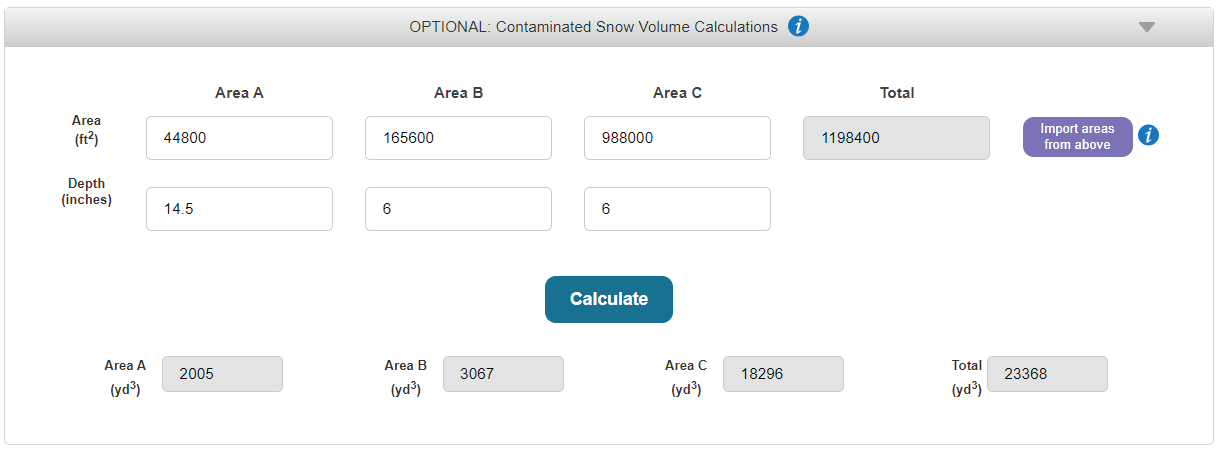

Using the "Contaminated Snow Volume Calculations" sub-calculator, the volume of contaminated snow in each plume area can be verified. If the optional sub-calculator is not visible, click the dropdown arrow to present the sub-calculator.

The results of the "Plume Area Calculations" can be imported by clicking the "import areas from above" button. The average depth of contamination for the scenario areas are listed in Table 2. In Table 2 for Area A, the average depth of contamination is estimated as 8.5 inches. Because it is difficult to precisely remove only the contaminated snow, as a reviewer, we make the conservative choice to add an additional six inches in depth of uncontaminated snow that will be inadvertently recovered along with the contaminated snow for a total of 14.5 inches. Because the plan notes a minimum depth for mechanical recovery of six inches, we will use depth of six inches for Area B and Area C.

NOTE: Because we are expecting to recover non-contaminated snow along with the contaminated snow, we will have to adjust the oil saturation of recovered snow to correctly estimate the volume of oil we can recover. See Table 6 for saturation adjustment calculations.

The inputs and resulting outputs of the volume calculation are shown in Figure 3:

Figure 3: Plume Volume Calculations Example

Figure 3: Plume Volume Calculations Example

As shown in Table 5, several errors in the anticipated planned volumes have been discovered during review. The volumes listed seem to account for only the actual volume of contaminated snow and not the volume that must actually be removed during recovery. In addition, the areas for Area A and Area B were incorrectly calculated. Because of these errors, the example scenario has underestimated the volume of snow that will be required to be removed in all three areas.

| Area | Planned Volume (cubic yards) |

ROSI Verification (cubic yards) |

Analysis |

|---|---|---|---|

| A | 1,175 | 2004.94 | Volume calculation listed in plan is incorrect |

| B | 426 | 3066.67 | Volume calculation listed in plan is incorrect |

| C | 616 | 18,296.30 | Volume calculation listed in plan is incorrect |

Additional Analysis of Simplified Example Scenario

Note that the trip haul distance in the plan lists round trip distance of 126 miles. Since the Calculator requires one-way distance, the correct data entry for "Haul Distance" will be 63 miles.

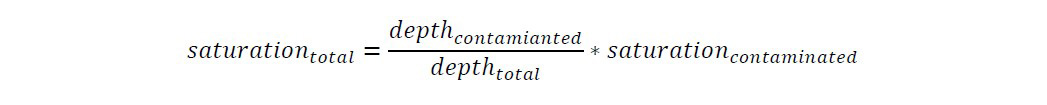

The oil saturation values listed in Table 2 do not include recovery of any non-contaminated snow. Since actual recovery will include non-contaminated snow with the contaminated snow the saturation rates must be adjusted to correctly estimate the quantity of recovered oil. The saturation values can be adjusted for additional non-contaminated snow according to the formula:

Calculations to adjust the saturation rates for this scenario are listed in Table 6:

| Area | Ratio of depth of contaminated to total snow recovered (depth in inches) |

Saturation of Contaminated Snow (from Table 2) (bbl / yd3) |

Adjusted Saturation (bbl / yd3) |

|---|---|---|---|

| A | 8.5 / 14.5 = 0.59 | 2.4 | 0.59 * 2.4 = 1.42 |

| B | 1.5 / 6 = 0.25 | 1.3 | 0.25 * 1.3 = 0.325 |

| C | 0.25 / 6 = 0.042 | 0.3 | 0.042 * 0.3 = 0.0126 |

These oil saturation values will be entered into the "Advanced Options" dropdown menu of the Calculator for each TWA.

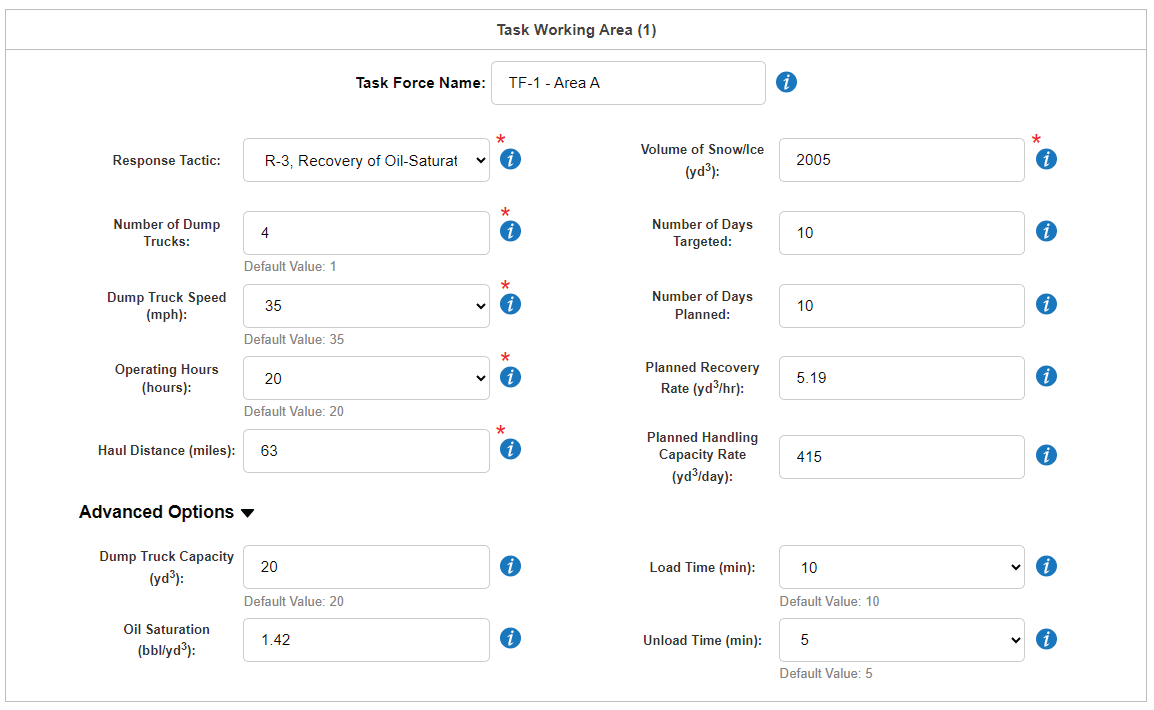

Recovery and Handling Capacity Scenario Verification Inputs

A total of three task working areas (TWAs) were identified. Click the "Add Additional Task Working Area" button twice, so three TWAs are present in the Calculator. Input for each TWA is based on the "Main Inputs Rational" list that follows. Figures 4-6 show the data inputs for the Calculator for the simplified example.

Main Inputs Rationale:

- Task Force Name: Sourced from simplified example, Table 3

- Response Tactic: Sourced from simplified example, Table 3

- Number of Dump Trucks: Sourced from simplified example, Table 3

- Dump Truck Speed: Not specified in simplified example; default speed used

- Operating Hours: Not specified in simplified example; default hours used

- Haul Distance: Used 1/2 of round-trip distance (equal to one-way distance) listed in Table 3 notes.

- Volume of Snow/Ice: Used volumes calculated in Table 6

- Number of Days Targeted: No regulatory requirement identified. Used number of days planned, from Table 3

- Number of Days Planned: Sourced from simplified example, Table 3

- Planned Recovery Rate: Sourced from simplified example, Table 3

- Handling Capacity: Sourced from simplified example, Table 3

Advanced Options Rationale:

- Dump Truck Capacity: Not specified in simplified example; default capacity used

- Oil Saturation: Adjusted saturation according to Table 5

- Load Time: Not specified in simplified example; default load time used

- Unload Time: Not specified in simplified example; default unload time used

Figure 4: Simplified Example TWA - A Inputs

Figure 4: Simplified Example TWA - A Inputs

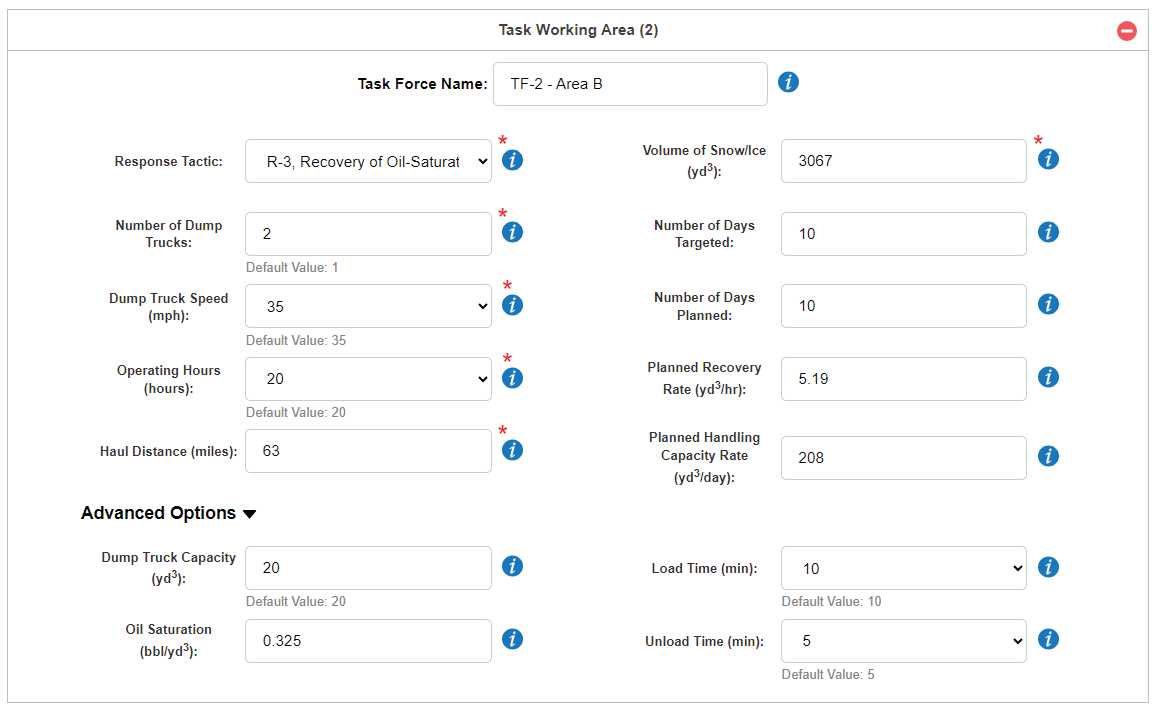

Figure 5: Simplified Example TWA - B Inputs

Figure 5: Simplified Example TWA - B Inputs

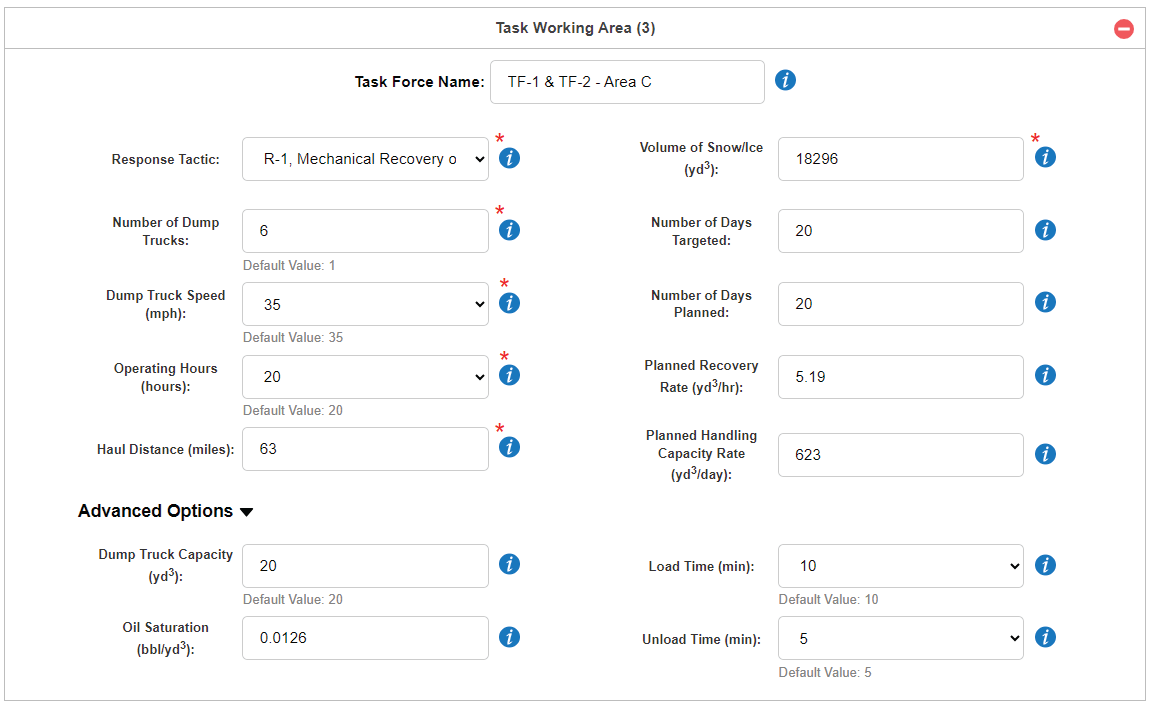

Figure 6: Simplified Example TWA C - Inputs

Figure 6: Simplified Example TWA C - Inputs

Output

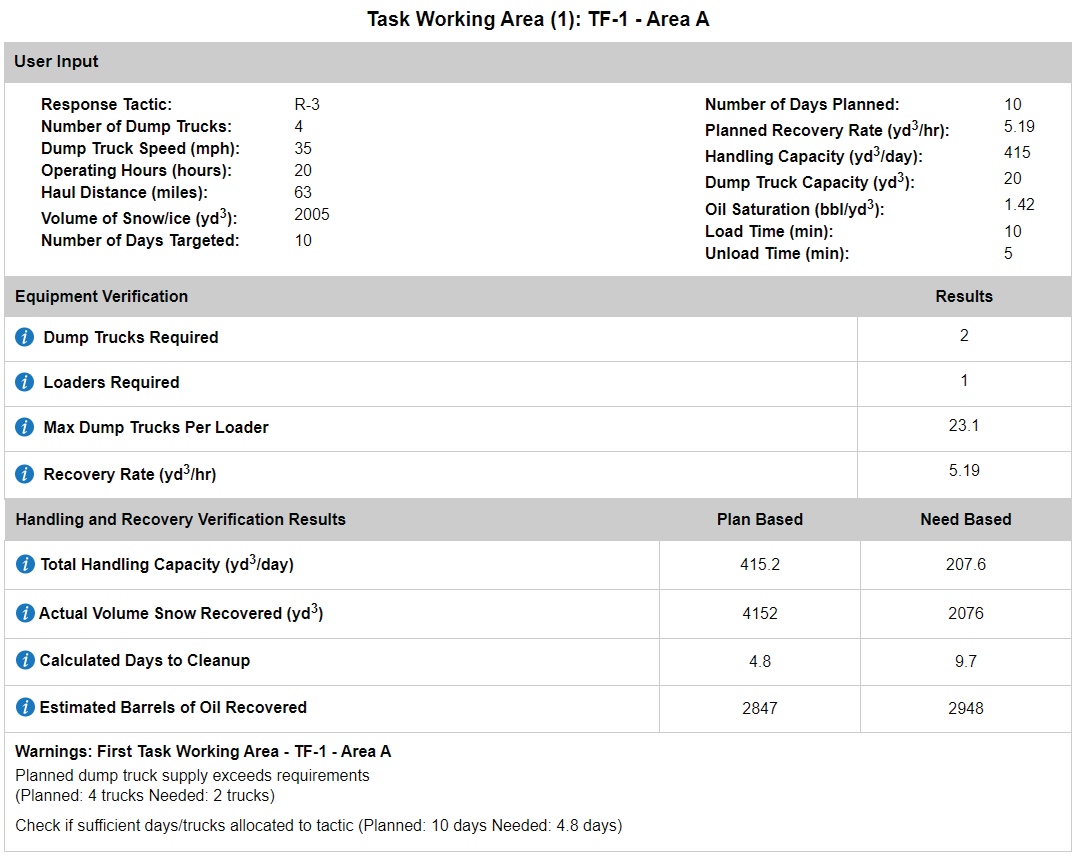

The output of the Calculator for task working area A is presented in Figure 7. Based on the results, the following issues were identified.

- The planned number of dump trucks is greater than required for this area. Either 2 trucks for 10 days or 4 trucks for 5 days would be sufficient.

- No errors with the planned recovery rate and handling capacity were identified in the review of the simplified example scenario. However, if the number of planned trucks is modified than the planned numbers for recovery rate and handling capacity will also require updating.

Figure 7: Output - Task Working Area A

Figure 7: Output - Task Working Area A

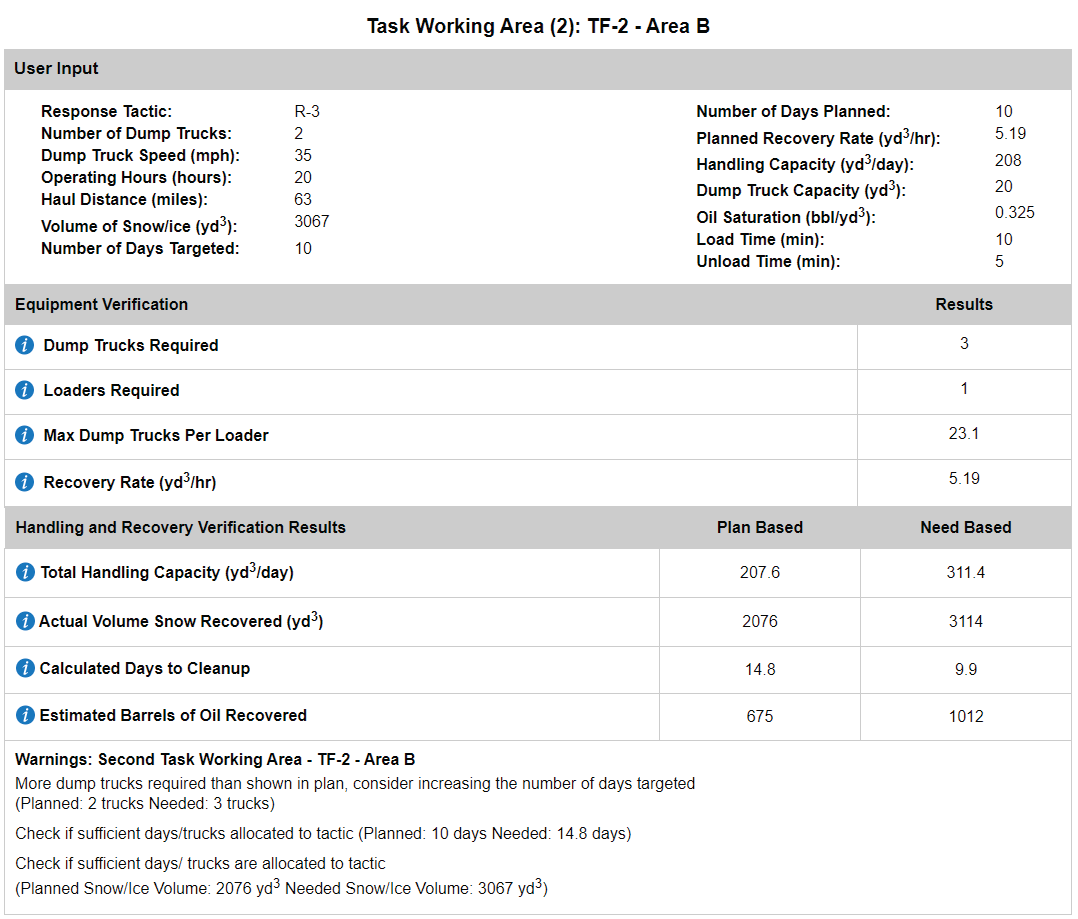

The output of the Calculator for task working area B is presented in Figure 8. Based on the results, the following issues were identified.

- The planned number of dump trucks is insufficient for this area. Either 3 trucks for 10 days or 2 trucks for 15 days would be sufficient.

- Due to an insufficient number of trucks the calculator generates a warning that insufficient volume of snow/ice will be recovered in the time allotted.

- No errors with the planned recovery rate and handling capacity were identified in the review of the simplified example scenario. However, if the number of planned trucks is modified than the planned numbers for recovery rate and handling capacity will also require updating.

Figure 8: Output Task Working Area B

Figure 8: Output Task Working Area B

The output of the Calculator for task working area C is presented in Figure 9. Based on the results, the following issues were identified.

- The planned number of dump trucks is insufficient for this area. Either 9 trucks for 20 days or 6 trucks for 30 days would be sufficient.

- One loader is sufficient to load up to 23 trucks (The plan listed two loaders available).

- No errors with the planned recovery rate and handling capacity were identified in the review of the simplified example scenario.

Figure 9: Output Task Working Area C

Figure 9: Output Task Working Area C

Conclusions

Based on the review of the simplified example scenario utilizing the ROSI Calculator, the following example review comments have been generated. These comments demonstrate feedback that is appropriate based on the issues identified in the review of the example scenario:

- The plume areas of task working areas B and C are underestimated in the scenario

- The volumes of recovered snow for task working areas B and C are underestimated due to the issue in the first bullet

- The volumes of recovered snow do not correctly include non-contaminated snow that will be recovered with the contaminated snow (this affects all task working areas)

- Due to underestimation of the recovery volumes for all task working areas, not enough equipment or time is allocated in the plan.

- Recommend re-evaluation of the areas/volumes contained in the plan to ensure sufficient equipment is available.

- The listed saturation of the snow does not correctly include the non-contaminated snow.

- This can lead to incorrect assumptions of oil recovery.

- Table 2 of the simplified example scenario plans to utilize tactic R-1 (Mechanical Recovery of Lightly Oiled Snow) in Area C. Mechanical recovery is expected to include recovery of non-contaminated snow that greatly exceeds the recovery of contaminated snow recovery.

- Consider utilization of a manual response tactic such as ACS tactic R-2 (Manual Recovery of Lightly Oiled Snow).

- Please note that ACS tactic R-2 is not supported by the ROSI calculator.

When conducting review of OSRP`s the following issues should be considered:

- Is anything missing from the plan to complete review of the handling and recovery capacity?

- Are the areas correctly calculated?

- Are the recovery volumes correctly calculated?

- Does the recovery volume include conservative estimates for non-contaminated snow and ice that will be recovered with the contaminated snow and ice?

- Does the oil saturation value assigned in the scenario include the unavoidable recovery of non-contaminated snow or ice if applicable?

- Is the limiting factor of cleanup equipment trucks (typical) or loading equipment?

Formulas Used

In the ROSI Calculator the following equations are used to estimate contaminated snow/ice recovery and handling capacity. Note that the use of USCU or metric has no bearing on the formulas used.

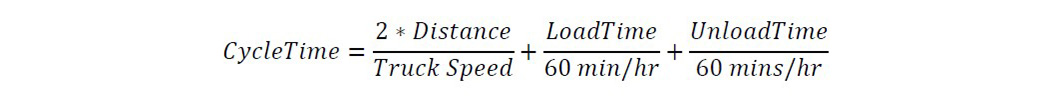

Dump Truck Cycle Time (CycleTime)

Dump Truck Cycle Time is the time it takes for one dump truck to complete one cycle of loading, unloading and two way travel time in hours.

Where,

Distance = the one way driving distance to the disposal site in miles

Truck Speed is the dump truck average transit speed in miles per hour

LoadTime is the time to load the dump truck by a loader in hours

DumpTime is the time to unload the truck in hours.

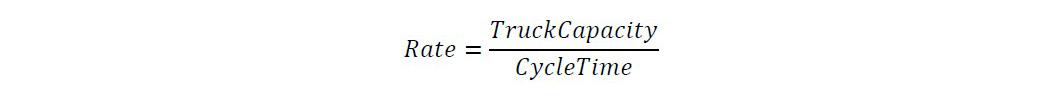

Recovery Rate (Rate)

Recovery Rate (Rate) is the rate of contaminated snow or ice recovery in cubic yards per hour for one dump truck.

Where,

TruckCapacity = Is the average volume that the dump truck can reasonably transport in cubic yards

CycleTime = Time for a dump truck to complete one round trip (formula above) in hours.

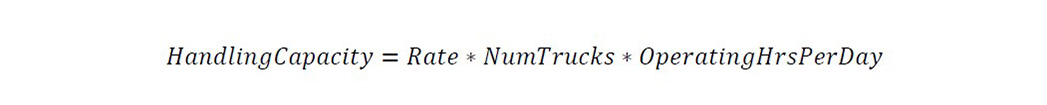

Daily Handling Capacity (Handling Capacity)

The Daily Handling Capacity is the volume of contaminated snow and ice that can be transported to the disposal site in one day using all available dump trucks measured in cubic yards.

Where,

Rate = Is the recovery rate for one dump truck (formula above) in cubic yards per hour

NumTrucks = The number of trucks available to haul contaminated snow and ice

OperatingHrsPerDay = The amount hours that equipment is expected to be production each day

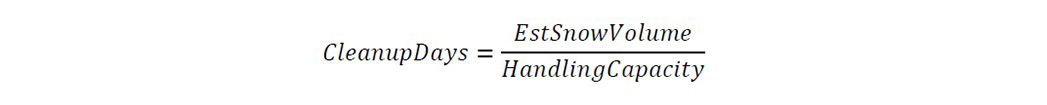

Calculated Days to Cleanup (CleanupDays)

The number of days that it will take to cleanup based on estimated snow volume and handling capacity.

Where,

EstSnowVolume = Is the volume of contaminated snow and ice that is present and recoverable by the chosen response tactic in cubic yards

HandlingCapacity = Is the volume of contaminated snow and ice that can be relocated in one day in cubic yards (formula above).

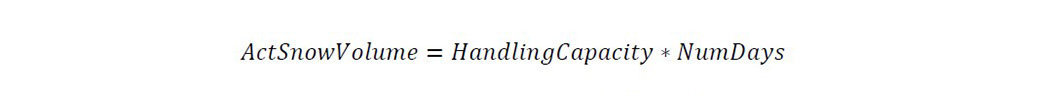

Actual Volume (Contaminated Snow/Ice) Recovered (ActSnowVolume)

The Actual Volume of contaminated snow and ice recovered (ActSnowVolume) is the volume of contaminated snow or ice that can be transported in the given timeframe.

Where,

HandlingCapacity = Is the daily total handling capacity (formula above)

NumDays = The number of days that equipment will be in operation (number of days targeted/planned).

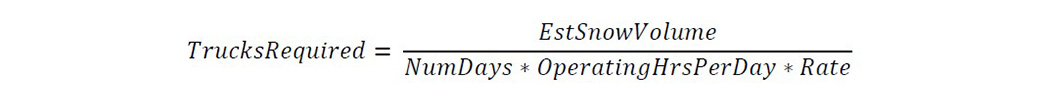

Dump Trucks Required (TrucksRequired)

Dump Trucks Required is the calculated number of dump trucks required to transport the given volume of contaminated snow or ice in the given number of days.

Where,

EstSnowVolume = Is the volume of contaminated snow and ice that needs to be transported to the disposal site

NumDays = The number of days that equipment will be workin

OperatingHrsPerDay = Operating Hours or the number of hours that equipment is expected to be in operation each day

Rate = Is the Contaminated Snow Recovery Rate (formula above) in cubic yards per hour

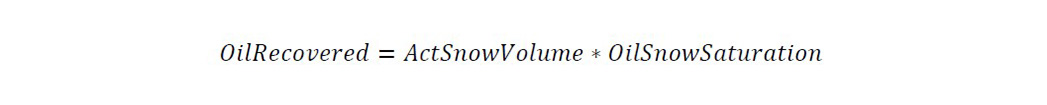

Estimated Barrels of Oil (OilRecovered)Estimated Barrels of Oil is an estimate of how many barrels of oil could be recovered based on the volume of snow or ice recovered and the average oil saturation of the snow.

Where,

ActSnowVolume = Actual Volume (Contaminated Snow/Ice) Recovered (formula above)

OilSnowSaturation = The average Oil Saturation of the snow in barrels of oil per cubic yard of snow/ice.

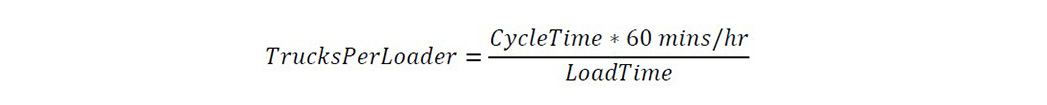

Maximum Dump Trucks per Loader (TrucksPerLoader)

Maximum Dump Trucks per Loader is the calculated number of dump trucks that one loader can load based on the loading and cycle time of the dump trucks.

Where,

CycleTime = Dump truck cycle time (formula above) in hours

LoadTime is the time to load the dump truck by a loader in minutes